HOW COMMERCIAL PROJECTS ARE DELIVERED

Our Commercial Construction Process

Every commercial construction project follows a defined delivery process. These processes dictate when the contractor is engaged, how design decisions are made, how pricing is established, and where risk ultimately lives.

On Time

On Budget

Higher Quality

Zero Surprises

What Makes Our Process Different

While most contractors operate within the same three delivery models, outcomes vary dramatically depending on when the contractor is involved, how costs are managed, and whether collaboration or competition is incentivized.

Understanding these delivery methods is the first step in understanding why Stronghold’s process produces different results.

INDUSTRY-DEFINED PROCESSES

The Three Standard

Commercial Construction

Delivery Methods

Across the U.S., commercial contractors operate under one of three primary construction delivery models. These methods are widely accepted and commonly used — particularly in Oklahoma and surrounding markets.

-

PRICE-DRIVEN SELECTION

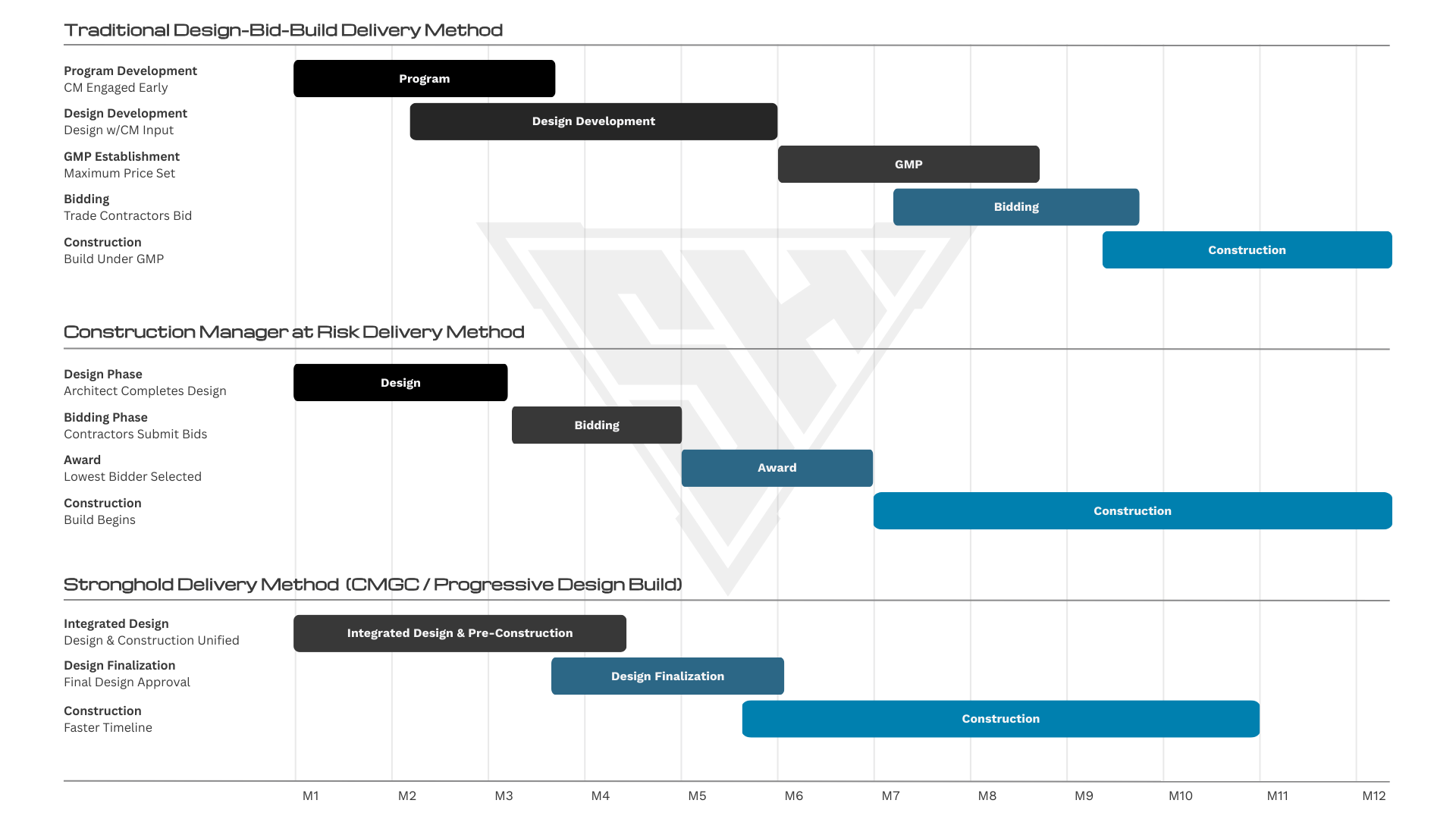

Design–Bid–Build is the most common commercial construction process. In this model, a designer or architect completes the full design before contractors are invited to bid. The project is typically awarded to the lowest-priced bidder.

Key characteristics:

Design and construction are fully separated

Contractor input occurs after design is complete

Trades are selected based primarily on price

Budget risk largely shifts to the owner after construction begins

Because contractors and trades are not involved during design, this method often leads to constructability issues, change orders, and budget surprises once work is underway.

-

EARLIER INVOLVEMENT, LIMITED INTEGRATION

Construction Manager at Risk introduces the contractor earlier in the process. The contractor provides pre-construction services and later delivers the project under a Guaranteed Maximum Price (GMP).

Key characteristics:

Contractor engaged during design

Budget estimates provided at design milestones

Contractor assumes some construction risk

Design and construction still operate in separate lanes

While CMAR offers improved visibility compared to low-bid delivery, it remains partially siloed and does not fully integrate trades or pricing early enough to eliminate downstream surprises.

-

SINGLE CONTRACT, SHARED CONTROL

In Design–Build delivery, the owner contracts with a single entity responsible for both design and construction. This model reduces handoffs and can accelerate schedules.

Key characteristics:

One contract for design and construction

Faster timelines through overlap

Reduced administrative complexity

Limited independent cost validation

While Design–Build can improve speed, it often reduces transparency unless safeguards are in place to independently validate pricing and risk.

STRUCTURE THAT CREATES SURPRISES

Where Traditional Delivery Methods Fall Short

Each of these delivery models functions within established industry rules — but two of these commonly suffer from the same structural issues:

X Contractors engaged too late to influence design decisions

X Pricing developed without full trade participation

X Risk pushed downstream to owners

X Limited cost transparency

X Adversarial dynamics between parties

A Better Commercial

Construction Process

Stronghold Construction operates within these same delivery frameworks — but executes them differently using a progressive, federally approved methodology known as CMGC / Progressive Design Build.

THE STRONGHOLD WAY

THE STRONGHOLD ADVANTAGE

A Process Built for Predictability

✓ Early Integration

We engage trade partners during design to ensure buildability before the first shovel hits the dirt.

✓ Real-Time Pricing

We provide open-book estimates validated by the current market, eliminating budget guesswork.

✓ Proactive De-Risking

We identify and resolve structural or site hurdles upfront to keep your timeline on track.

Why This Process Matters

Most commercial construction failures are not execution problems — they are process problems. Stronghold’s methodology exists to eliminate uncertainty before it reaches the jobsite. By restructuring the commercial construction process around early collaboration, transparency, and accountability, Stronghold delivers projects that are predictable, profitable, and built to last.

Ready to start your next project?

A Commercial Construction Process Built for Modern Projects

Stronghold Construction provides owners with a modern commercial construction process designed for today’s projects — not outdated systems that create chaos.